For example, if the actual material cost is higher than the standard cost, it may indicate issues with procurement or wastage that need to be addressed. Setting accurate standard costs is Certified Public Accountant crucial for the effectiveness of standard costing. Organizations typically consider historical data, industry benchmarks, and expert opinions to determine standard costs. For materials, factors such as purchase prices, freight costs, and spoilage rates are taken into account. Labor standard costs are based on wage rates, productivity levels, and allowances. Overhead standard costs involve estimating costs related to indirect materials, utilities, and depreciation.

Video Illustration 8-2: Computing direct materials variances

Let’s see how these standard costs apply in a real-world example to understand better. Once the three calculations have been done, they are all added together to create a single standard cost for the company. In this plan variances are expressed as percentages and not in absolute standard costing monetary terms. This plan provides the same information as is provided by the single plan.

How are Industry Benchmarks Used in Standard Costing?

Sign into Fisbowl Communities and gain access to support requests, product documentation and software downloads. Learn how Inventory management ensures the right stock balance to meet demand and maximize efficiency. Our most robust, cloud hosted inventory tracking, warehousing, and manufacturing solution with hosted capabilities. Standard costing helps in distinguishing between skilled and unskilled activities. So the skilled worker only gives pays attention to improving the activities of the unskilled workers. Past records can be used only to assess ‘normal’ wastes, machine breakdown, level of efficiency, etc.

Standard costs variance template

- Select an allocation base, such as machine hours or human hours, that accurately reflects how production uses overhead resources.

- By comparing actual costs to standard costs, businesses can identify variances, analyze their causes, and take corrective actions to enhance efficiency and profitability.

- There are many applications in which it is too time-consuming to stop and collect the actual cost.

- This does not mean the actual costs will never be used, typically a company’s accountant will periodically update the variances as that information becomes available.

- However, use of sophisticated forecasting techniques can assist to a great extent.

- With Viindoo, businesses can make informed decisions about pricing, investments, and other strategies based on accurate and up-to-date information.

With the exception of the hourly rates, all of these numbers will need to be estimated. Design reports that highlight exceptions rather than drowning managers in data. Use visual cues—traffic light colors work well—to quickly identify problem areas. Overly aggressive standards demoralize employees, while overly lenient ones fail to drive improvement. Finding that sweet spot — challenging but achievable — requires both technical knowledge and good judgment about human motivation.

It also offers vital insights into process improvement and resource allocation. Using standard costs simplifies the computation of inventory values and cost of goods sold. This strategy ensures that financial statements are reported faster and more consistently.

By setting these standards, businesses can monitor labor efficiency and identify areas for improvement. When managers have controlled costs through the use of the standard costing system, the actual costs in the future should be close to the standard costs. This outcome is highly favorable because this means that the profit plan went as projected. Now, add together the standard costs for direct materials, direct labor, and overhead. The total represents the https://www.seyyahyollarda.com/blockchain-in-accounting-a-guide-for-tax.html standard cost of producing one unit of your product or delivering one unit of your service.

- Companies that deal with adverse conditions may opt for applying standard costing.

- This method helps you stay on budget and make better financial decisions.

- Remember, standard costs are not static; they evolve with changing circumstances.

- This outcome is highly favorable because this means that the profit plan went as projected.

- (1) Organisation Structure – Standard costing demands the existence of a sound organisation structure with well-defined authority relationships.

- The quantity standard establishes how much of an input is needed to make a product or provide a service.

Difference between Standard Cost and Estimated Cost

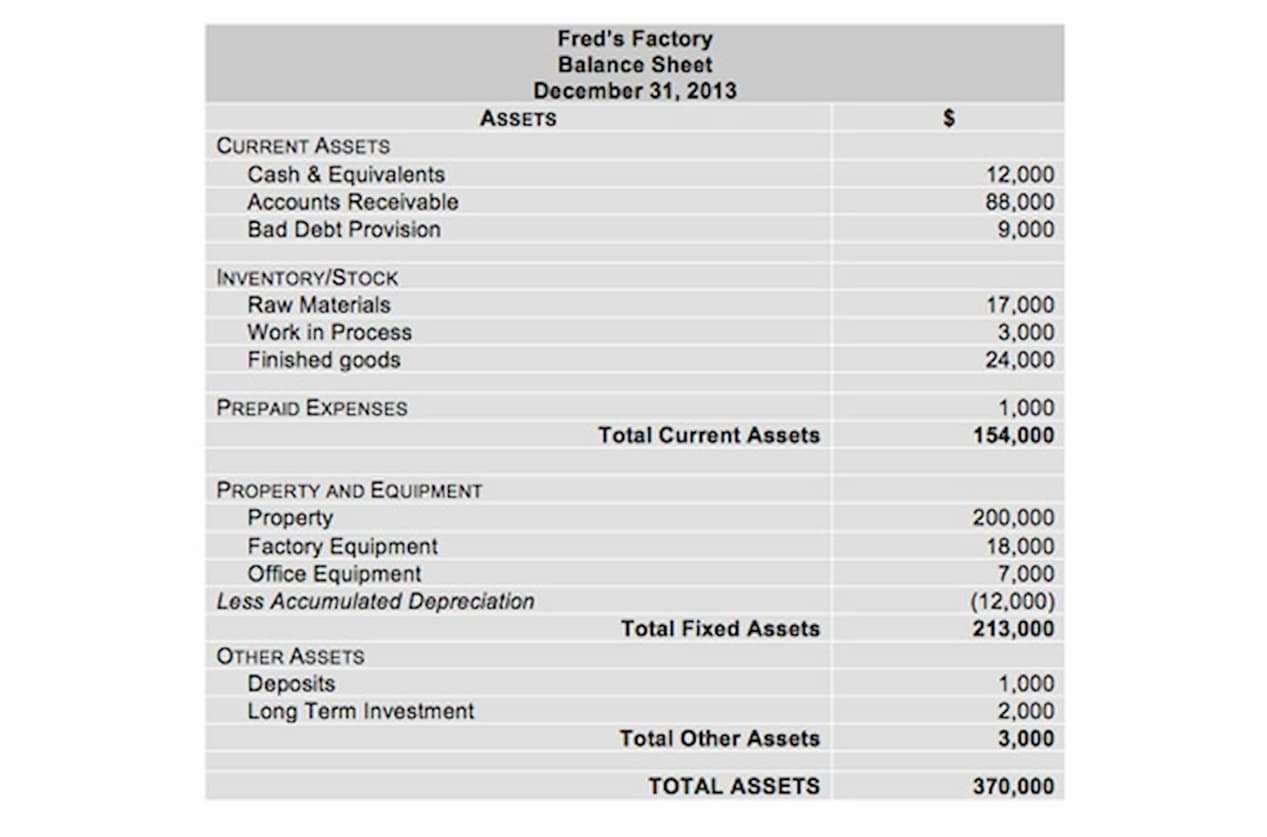

Fixed manufacturing overhead is analyzed by comparing the standard amount allowed to the actual amount incurred. The completed top section of the template contains all the numbers needed to compute the direct labor efficiency (quantity) and direct labor rate (price) variances. The direct labor efficiency and rate variances are used to determine if the overall direct labor variance is an efficiency issue, rate issue, or both. At the beginning of the period, Brad projected that the standard cost to produce one unit should be $7.35.

You run the business, we automate the details

These predetermined costs are based on careful analysis and are set as benchmarks against which actual costs are compared. Essentially, standard costing creates a cost plan, or “standard,” that the company aims to achieve in its production processes. Standard costing sets predetermined cost benchmarks to evaluate actual performance, enabling variance analysis and cost control. It covers direct materials, labor, and overheads, using ideal, attainable, or basic standards. Variance analysis highlights deviations in price, usage, efficiency, and overheads—guiding corrective action and continuous improvement.

Direct Labor Calculation

In our hotel example, you’d sum the costs of cleaning supplies, labor, and allocated overhead to get the standard cost of turning over a room, as we did in the introduction to this piece. Standard costing is an effective strategy for controlling costs, improving budget accuracy, and assessing performance, particularly in stable production environments. It lays you a clear framework for tracking spending and identifying areas for improvement. Businesses can keep tighter financial control by comparing actual costs to pre-determined benchmarks. This strategy also helps with decision-making by giving consistent and dependable cost data. For example, at the beginning of a year a company estimates that labor costs should be $2 per unit.